BDS – Magnetic Drilling Machines and Core Drilling Cutters

Magnetic Base Drilling Machine are the flagship product of BDS Maschinen®. We have specialized in manufacturing magnetic foot drills since 1989, hence our focus on this product line.

We currently have the widest range of magnetic drills in the world. We manufacture more than 27 models of magnetic drilling machines as standard models. We also manufacture magnetic drilling machines for special purposes.

Our magnetic drilling machines are equipped with powerful magnets that can firmly secure the machine to a wide range of ferrous materials, including steel, iron, and other metals. This feature ensures stability and minimizes the risk of workpiece movement during drilling, which is crucial for precision work.

We offer a wide selection of core drilling cutters that are specifically designed to work seamlessly with magnetic drilling machines. These cutters are engineered to provide optimal performance, longevity, and compatibility with various materials.

SFTC is the largest Magnetic Drilling Machines Suppliers. Find the perfect equipment for your industry requirements below.

Products

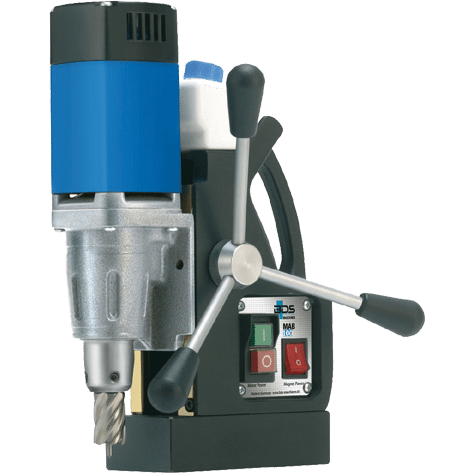

The lightest magnetic drill on a BDS machine weighs only 9.9 kg (21.82 lbs). The new generation MAB 100K renews the old model MAB 100. The new lightweight magnetic drill MAB 100K is equipped with a 19 mm (3/4″) Weldon keyless drill chuck system.

The MAB 100K Lightweight Magnetic Excavator is the best entry point into successful technology where professional users expect a mature and robust machine built for continuous use. This compact magnetic drill has a minimum height of 318 mm (12 33/64 inches), a maximum height of 383 mm (15 5/64 inches) and a working stroke of 70 mm (2 3/4 inches). The MAB 100K has a working stroke of only 70 mm (2 3/4 inches), but the machine can be used for twist drilling. The specially developed “BDS Twist Drill with Weldon Shank (SPS)” eliminates the need for a drill chuck adapter (reduces machine stroke). Just attach the dedicated twist drill to the keyless drill chuck of this machine. For more information, watch the MAB 100K product video.

This ultralight magnetic drill can drill up to 30mm (1 3/16″) diameter and 55mm (2 11/64″) depth of cut. The magnetic drill is equipped with a new 1050 watt (9.5 amp) motor, also made in Germany. MAB 100K models are available in 230 and 110 volts at 50-60 Hz.

A great feature of the MAB 100K lightweight magnetic drill is the complete internal wiring. Coming out of the machine’s stand, you may not be able to see the cables that connect to the machine’s motors. This internal wiring makes transporting the machine easy, convenient, and safe, even in towers and prefabricated steel structures.

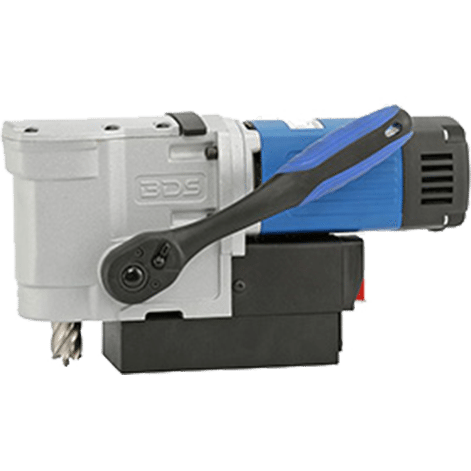

The brand new MAB 155 Compact Horizontal Magnetic Drilling Machine The MAB 155 is a relaunch of the previous generation MAB 150 model, with a completely new design and a powerful new German brand motor. The lightweight and compact MAB 155 is the ideal magnetic drill for drilling in demanding conditions such as bridge maintenance, H-beam drilling, and pre-drilled structures.

The ultra-compact magnetic drilling machine MAB 155 is only 180 mm high and weighs only 11 kg. (24 lbs). The new MAB 155 magnetic drill is equipped with a new 1050 watt (9.25 amp) single speed available in 230 volt and 10 volt (50-60 Hz) versions. The MAB 155 has a safety switch.

A nice feature of the MAB 155 is that the machine is equipped with a ratchet. Therefore, depending on the digging situation, the feed handle can be used from either the left or right side.

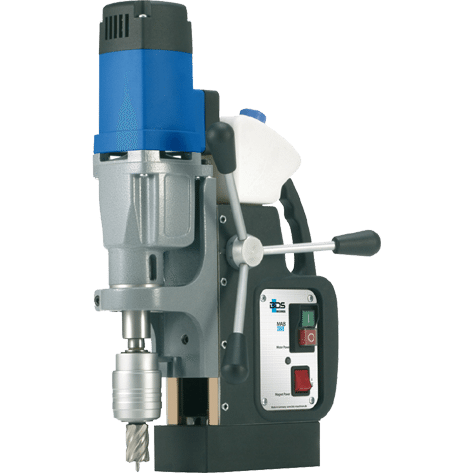

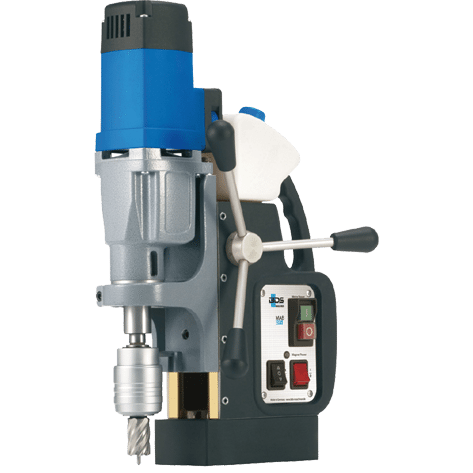

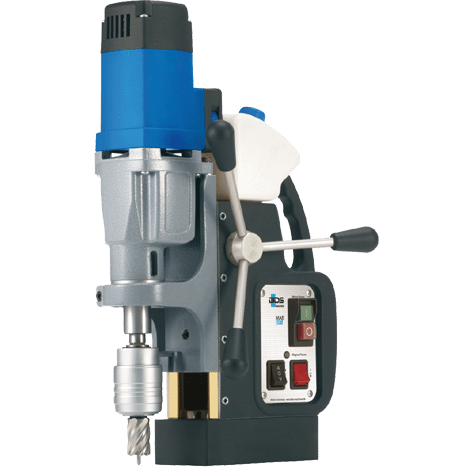

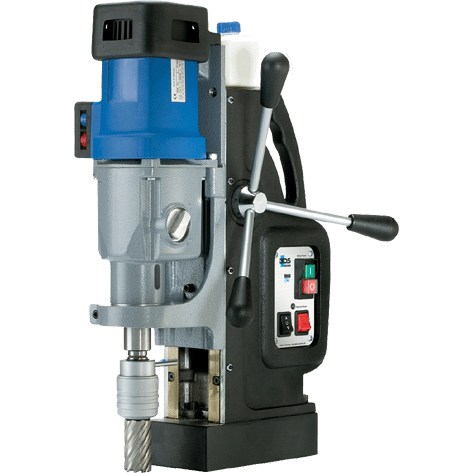

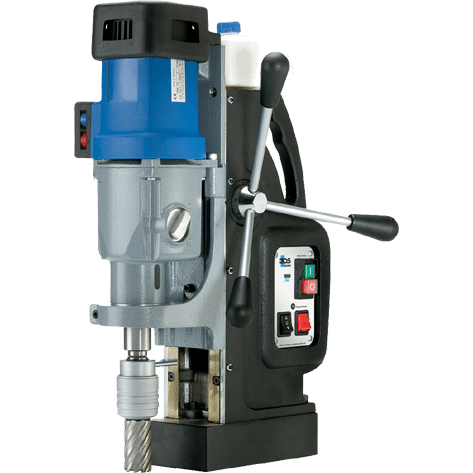

The high performance magnetic drill MAB 455 is “Made in Germany” with power and performance for heavy drilling tasks. The MAB 455 High Performance Magnetic Drilling Machine is a very powerful machine for the PEB industry, steel industry, assembly and workshops of all kinds.

The main advantage of the MAB 455, a high performance magnetic drill, is its robust next generation gearbox, equipped with an oil-immersed gearbox that provides a long service life. Using an oil bath gearbox ensures that all gears in the gear unit are lubricated. If the gears are properly and evenly lubricated, the gearbox will not heat up easily and the gears will not wear out. Other great features of the MAB 455 High Performance Magnetic Drill include a magnetic attachment indicator that tells the operator if the material thickness or material surface is suitable for magnetic attachment. This is a very important feature for operator safety and to prevent tool damage. The MAB 455 receives full internal wiring. This makes magnetic drills more manageable and easier to use, especially when drilling steel structures. The cable that connects the motor to the switch is internal instead of external, which also improves the aesthetics of the machine.

The MAB 455 high performance magnetic drill is also equipped with a 19 mm (3/4 inch) Weldon quick action drill chuck system. A keyless drill chuck allows quick and easy tool changes. Special BDS twist drills with Weldon shanks can now be mounted directly onto quick action drill chucks without the need for additional conventional drill chuck holders. Keyless drill chucks also help prevent tool breakage.

The MAB 455 high performance magnetic drill has a drilling capacity of 40 mm (Ø 2-1/16″) diameter, 55 mm (2 11/64″) cutting depth with ring cutter, 18 mm (Ø 7/8 inch). It comes with a twist drill.

230 V or 110 V powerful 1150 Watt (10.5 Ampere) German brand motor with 2 speed gearbox at 250 or 450 rpm respectively. The MAB 455 high performance magnetic drilling machine has a working stroke of 160 mm (3 1/3 inches).

The powerful Morse Taper 2 (MK 2) increases the versatility of the MAB 455 high-performance magnetic drill. It weighs only 13kg. (29 lbs) The MAB 455 is a truly portable and sturdy magnetic drill.

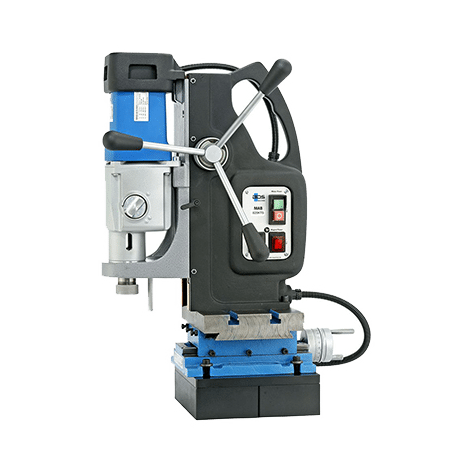

A magnetic drill with a MAB 455 SB turntable, made in Germany. It performs particularly well in steel structures, during assembly and in workshops. The rotating base adjustment of the magnetic drill makes it easy to find the center of the hole. The operator is greatly relieved when drilling operations are overlooked or performed in a horizontal position. Good ideas are born:

BDS now offers four of his magnetic drilling machines with moving magnet adjustment in two performance classes. How the swivel base works:

Simply attach it to a magnetic drill, activate the magnet, and release the adjuster for easy adjustment. The swivel base allows the magnetic drill to be precisely positioned without having to support the full weight of the machine at the same time. Even if the machine is chained down, this relief is an additional element for increased work safety.

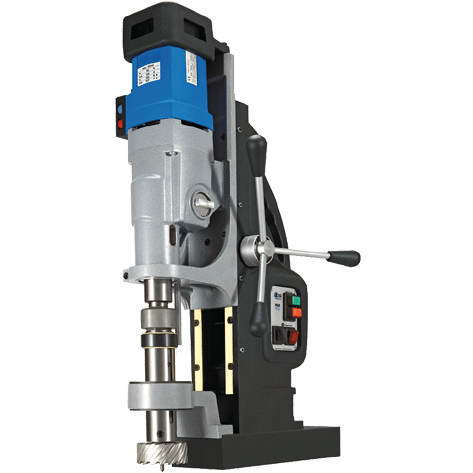

The heavy magnetic drilling machine MAB 455 SB is “Made in Germany” with power and performance for heavy excavation work. The MAB 455 SB High Performance Magnetic Drilling Machine is a very powerful machine for the PEB industry, steel industry, assembly and workshops of all kinds. A key advantage of the MAB 455 SB, a high-performance magnetic drill, is a robust next-generation gearbox, equipped with an oil-immersed gearbox that provides a long service life. Using an oil bath gearbox ensures that all gears in the gear unit are lubricated. If the gears are properly and evenly lubricated, the gearbox will not heat up easily and the gears will not wear out.

Another great feature of the MAB 455 SB High Performance Magnetic Drilling Machine is the Magnetic Adhesion Display, which tells the operator if the material thickness or material surface is suitable for magnetic adhesion. This is a very important feature for operator safety and to prevent tool damage. The MAB 455 SB receives full internal wiring. This makes magnetic drills more manageable and easier to use, especially when drilling steel structures. The cable that connects the motor to the switch is internal instead of external, which also improves the aesthetics of the machine.

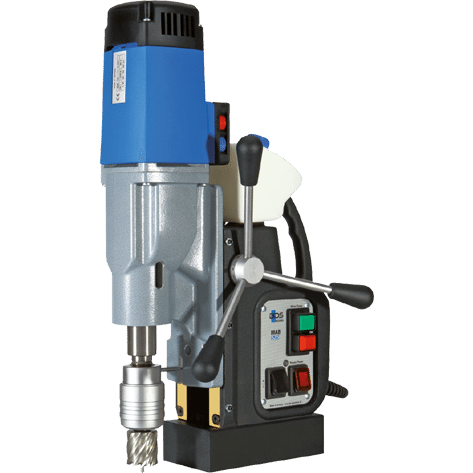

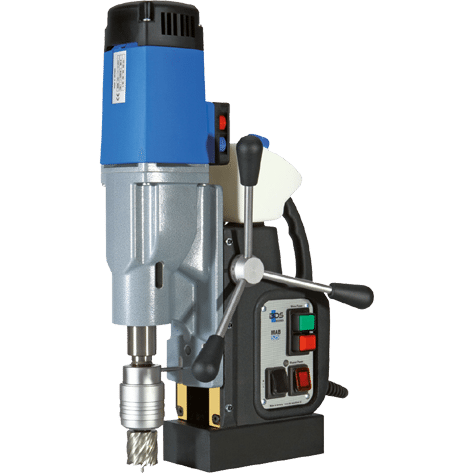

An inexpensive German-made MAB 465 magnetic drilling machine is equipped for drilling and threading operations. With its reversible motor and stepless speed control, the MAB 465 magnetic drilling machine is the perfect machine for drilling, tapping, countersinking, and reaming.

The lightweight magnetic drill MAB 465 is equipped with a 19 mm (3/4 inch) Weldon direct mandrel and powerful magnets. The MAB 465 magnetic drilling machine is also equipped with an intelligent magnetic display.

This portable magnetic drill features full internal wiring to prevent accidents when drilling in overhead or horizontal positions. The MAB 465 magnetic drilling machine is equipped with a cheap and powerful grease gear motor made in Germany.

The MAB 465 electromagnetic drill can drill up to 40 mm (2-1/16″) diameter with a cutting depth of 55 mm. The maximum tapping capacity of the machine is M16 (15/16 inch). The MAB 465 magnetic drilling and tapping machine is available in both 230 and 110 volt versions.

A custom “BDS Twist Drill with Weldon Shank (SPS)” allows the MAB 465 to be used without a drill chuck holder.

The best entry into the ProfiPLUS class of magnetic drilling and threading machines – essential in the workshop or on the go. The All-in-One MAB 485 is the ideal machine for drilling. Tapping, countersinking, rubbing.

The MAB 485 Magnetic Drill and Tapping Machine is equipped with an 1150 Watt (10.5 Amps) German brand motor and can be used on both 230 and 110 volts at 50-60 Hz. The MAB 485 magnetic drill and tapping machine has a stroke of 160 mm (6 19/64 inches). The lightweight magnetic drilling and tapping machine MAB 485 weighs only 13 kg.

A great feature of this magnetic drill and tapping machine is that it is equipped with a keyless chuck system. The MAB 485 magnetic drilling and tapping machine is a two-speed geared machine with innovative oil bath gears that extend the life of the machine.

Other great features of the MAB 485 Magnetic Drilling and Tapping Machine are full-wave control electronics for constant power output even while drilling, magnetic stick indicators for safety, overheat protection for extended armature and field coil life, and switching possible motor. Clockwise and counterclockwise rotation to facilitate tapping (thread cutting). The MAB 485 magnetic drilling and tapping machine is our best-selling machine on the German market.

The magnetic drilling and tapping machine MAB 485 SB – best entry in the ProfiPLUS category – with rotary table adjustment. Significant relief for the operator during excavation operations in overhead or horizontal positions. Good ideas are born:

BDS now offers four of his machines with moving magnet adjustment in two performance classes.

The All-in-One MAB 485 is the perfect machine for drilling, threading, and countersinking. Rub. The MAB 485SB magnetic drill is equipped with an 1150-watt (10.5 amp) German motor and can be used on both 230 and 110 volts at 50-60 Hz. The stroke of the MAB 485SB magnetic drilling machine is 160 mm (6 19/64 inches). The lightweight magnetic drill MAB 485SB weighs only 13 kg. A great feature of this magnetic drill and tapping machine is that it is equipped with a keyless chuck system. The MAB 485SB magnetic excavator is a two-speed geared machine with innovative oil bath gears that extend the life of the machine.

Other great features of the MAB 485SB Magnetic Drill Tapping Machine include full-wave control electronics for constant power output even while drilling, a magnetic stick indicator for safety, overheat protection for longer armature and field coil life, and a reversible integrated motor. Right Hand – and Counter-Clockwise Rotation Clockwise rotation facilitates tapping (tapping). The MAB 485SB Magnetic Drilling Machine is the best-selling machine on the German market.

MAB 525 Magnetic Drill/Tapping Machine – Robust and lightweight! MAB 525 MAB 525 Magnetic Drill/Tapping Machine Benefits Ideal for service work:

A total weight of just 16 kg, MT 3 tool holder and drilling capacity up to ø 50 mm, a torsion-resistant design, monobloc gears, and slides.

High-Performance Magnetic Drilling/Tapping Machine The MAB 525 is an all-around magnetic drilling/tapping machine for drilling, threading, and countersinking. Rub. A great feature of the MAB 525 magnetic drill/tap machine is the carbon brush indicator that lets the operator know when to replace worn carbon brushes. This will prevent damage to the armature.

Another feature is the reversible motor that allows the MAB 525 Magnetic Drill/Tapping Machine to perform tapping (tapping) operations very easily. A reversible motor ensures that the quality of the yarn produced is not compromised. The MAB 525 Magnetic Drilling/Tapping Machine is also equipped with intelligent overheat protection to prevent machine damage from overheating, extending the life of the armature and field coils with or without magnetization. The MAB 525 magnetic drilling/tapping machine’s full-wave control electronics provide constant power during drilling. The MAB 525 is a Morse Taper 3 (MK3) machine capable of taper shank twist drills up to 20 mm in diameter. The MAB 525 magnetic drilling/tapping machine is a speed gear machine with an oil bath gearbox. Oil bath gears are the most sophisticated gears available for magnetic drills and have a very long life compared to grease gears. The MAB 525 magnetic drill/tapping machine is equipped with a keyless drill chuck for easy replacement of core drills with Weldon shanks. The MAB 525 magnetic drill/tap weighs only 16 kg (35 lbs) and has a working stroke of 160 mm (6 19/64 in).

MAB 525SB Magnetic Core Drill Machine with Swivel Foot – Essential for any assembly or workshop. It’s versatile and ruggedly built. It is easy to place thanks to the swivel base. The advantages of the MAB 525 bogie are perfect for service work.

The total weight is only 16 kg. With an MT 3 tool holder and drilling capacity up to ø 50 mm, torsion resistant design, monobloc gears and slides. Swivel base for easy adjustment of drill position. MAB 525SB Magnetic Core Drill Machine with Swivel Foot – Essential for any assembly or workshop. It’s versatile and ruggedly built. It is easy to place thanks to the swivel base. The advantages of the MAB 525 bogie are perfect for service work.

total weight of just 16 kg. MT 3 tool holder with drilling capacity up to 50 mm, anti-torsion design, monobloc gears and slides. Swivel base for easy adjustment of drill position. The MAB 525SB Heavy Duty Magnetic Core Drill Machine with Swivel Base is a versatile magnetic drilling/tapping machine that performs drilling, threading, and countersinking. A great feature of the MAB 525SB swivel base magnetic core drill is the carbon brush indicator. This helps to timely notify the operator to replace the worn-out carbon brushes and avoid damage to the armature.

Another feature is the reversible motor that allows the MAB 525SB Swivel Base Magnetic Core Drill to perform tapping (tapping) operations very easily. A reversible motor ensures that the quality of the yarn produced is not compromised. The MAB 525SB Swivel Base Magnetic Core Drill is also equipped with intelligent overheat protection that prevents machine damage from overheating and extends armature and field coil life. The magnet display on the MAB 525SB Swivel Base Magnetic Core Drill lets the operator know if the machine’s

The magnet display on the MAB 525SB Swivel Base Magnetic Core Drill lets the operator know if the machine’s magnets are properly magnetized to the material being drilled. The full-wave control electronics of his MAB 525SB magnetic core drill machine with swivel base provide constant power during drilling. The MAB 525 is a Morse Taper 3 (MK3) machine capable of taper shank twist drills up to 20 mm in diameter.

The MAB 525SB Swivel Base Magnetic Core Drill is a speed geared machine with an oil bath gearbox. Oil bath gears are the most sophisticated gears available for magnetic drills and have a very long life compared to grease gears. The MAB 525SB magnetic core drill with swivel base is equipped with a keyless drill chuck for easy replacement of core drills with Weldon shanks. The MAB 525SB Swivel Base Magnetic Core Drill weighs only 16 kg (35 lbs) and has a working stroke of 160 mm (6 19/64 in).

The best magnetic drilling machine, MAB 825, made in Germany – full performance and flexibility for steel, plant and mechanical engineering. The advantages of MAB 825 are: Large series classic – with MT 3, for core drills with cutting depths of 30 mm, 55 mm, 75 mm, 110 mm, twist drills, reamer chucks, countersinks, threads great for cutting systems.

Outstanding advantages of the MAB 825 magnetic drilling machine:

Friction Clutch – The MAB 825 magnetic drill is equipped with a friction clutch that helps prevent tool breakage. When the cutter gets caught in the material and cannot rotate, the friction clutch operates to stop the rotation of the main shaft and prevent damage to the cutter.

Reversible Motor – For thread cutting and tapping you absolutely need a reversible motor. Once you have finished threading, the reversible motor allows you to remove the tap at the entrance of the hole, avoiding damaging the thread. The reversible motor is also suitable for right-handed and left-handed people.

Torque Control – The special torque control of the best magnetic drill MAB 825 gives the operator the exact power needed for drilling, tapping, reaming and countersinking. For example, tapping operations require high power and low speed, which can be achieved with his MAB 825 high power magnetic drilling machine.

Speed Control – This speed control helps the operator to get the exact speed required by the machine depending on the size or diameter of the cutting tool. The BDS ProfiPLUS class magnetic drilling machines are equipped with potentiometers for speed control, providing the correct speed and torque required when drilling, tapping, turning and countersinking.

Full Wave Control Electronics – Full wave control electronics allows the motor to provide the same power while drilling as it does at idle. Electronic control continuously adjusts the motor power to the load while drilling. The advantage is high performance at low speed and smooth flow. If the load peaks are too high, electronic torque control is activated to prevent tool breakage and avoidable damage. A positive contribution to employee safety by BDS machines.

MAGNETIC INDICATOR – This helps the operator know if the machine’s magnetic base is properly positioned on the material. If the machine is not positioned correctly, the LED indicator will light up to alert the operator to position the machine correctly. Load configurations and electromagnet reserves are precisely matched to the performance of each magnetic core drill machine. The user is notified by a visual check. Green LED:

Magnetic attraction meets minimum requirements. LED red:

The magnetic attraction is not good enough because thin material or paint layer, scale, zinc or improper placement will reduce the magnetic attraction.

Overheat Protection – Overloading or improper handling of the machine while drilling can cause the machine to heat up and the heat can damage the motor. The BDS magnetic drill protects the machine from overheating by stopping the motor when the sensor detects overheating, preventing damage to the motor. Let the machine idle for 30 seconds to he 1 minute after the engine has stopped due to overheat protection, then restart the engine without drilling. Let the motor run for a minute, then start drilling again. This feature extends machine life and prevents accidents.

CARBON BRUSH WEAR INDICATOR – The BDS magnetic drill’s carbon brush indicator solves this problem. When the carbon brushes are “worn out”, this indicator lights up red, letting the operator know that the carbon brushes should be replaced soon. The display provides advance notice so operators can order new carbon brushes without interrupting work on the machine.

MAB 845 made in Germany – highest performance and flexibility for steel, plant and mechanical engineering. Benefits of MAB 845 include: Swivel foot, adjustability for easy positioning of the drill, with large series Classic – MT 3, 110 mm for core drills with cutting depths 30 mm, 55 mm, 75 mm, twist drill, reamer chuck, countersink , suitable for threading systems.

The outstanding advantages of the MAB 845 Best Magnetic Drilling Tapping Machine:

Swivel Base (Optional) – The swivel base is an alignment device for BDS magnetic core drilling machines that helps the operator position the machine “even in magnetic conditions”. The operator can move the machine 30° left and right and 20mm back and forth when the magnet is activated. This is useful when drilling multiple holes in close proximity (such as boiler plates) or when drilling vertically or overhead.

Friction Clutch – The MAB 845 magnetic drill is equipped with a friction clutch that helps prevent tool breakage. The friction clutch operates to stop the rotation of the main shaft and prevent damage to the cutter when the cutter gets caught in the material and cannot rotate.

Reversible Motor – For thread cutting and tapping, you absolutely need a reversible motor. Once you have finished threading, the reversible motor allows you to remove the tap at the entrance of the hole, avoiding damaging the thread. The reversible motor is also suitable for right-handed and left-handed people.

Torque Control – The special torque control of the best magnetic drill, MAB 845, allows the operator to get the correct power required for drilling, tapping, reaming, and countersinking. For example, tapping operations require high power and low speed, which can be achieved with the MAB 845 high power magnetic drilling machine.

Speed Control – This speed control helps the operator get the exact speed the machine needs based on the size or diameter of the cutting tool. The BDS ProfiPLUS class magnetic drilling machines are equipped with potentiometers for speed control, providing the correct speed and torque required when drilling, tapping, turning, and countersinking.

Full Wave Control Electronics – Full wave control electronics allow the motor to provide the same power while drilling as it does at idle. Electronic control continuously adjusts the motor power to the load while drilling. The advantage is high performance at low speed and smooth flow. If the load peaks are too high, electronic torque control is activated to prevent tool breakage and avoidable damage. A positive contribution to employee safety by BDS machines. MAGNETIC INDICATOR – This helps the operator know if the machine’s magnetic base is properly positioned on the material. If the machine is not positioned correctly, the LED indicator will light up to alert the operator to position the machine correctly. Load configurations and electromagnet reserves are precisely matched to the performance of each magnetic core drill machine. The user is notified by a visual check. Green LED:

“Magnetic attraction” meets the minimum requirements. LED Red:

The magnetic attraction is not good enough because thin material or paint, scale, zinc layer, or improper placement will reduce the magnetic attraction.

Overheat Protection – Overloading or improper handling of the machine while drilling can cause the machine to heat up, and the heat can damage the motor. The BDS magnetic drill protects the machine from overheating by stopping the motor when the sensor detects overheating, preventing damage to the motor. Let the machine idle for 30 seconds to he 1 minute after the engine has stopped due to overheating protection, then restart the engine without drilling. Let the motor run for a minute, then start drilling again. This feature extends machine life and prevents accidents.

CARBON BRUSH WEAR INDICATOR – The BDS magnetic drill’s carbon brush indicator solves this problem. When the carbon brushes are “worn out,” this indicator lights up red, letting the operator know that the carbon brushes should be replaced soon. The display provides advance notice so operators can order new carbon brushes without interrupting work on the machine.

Oil bath gear – The motor gear of the BDS magnetic drilling machine consists of an oil bath. The advantage of BDS oil bath gearboxes is that the oil is always in a liquid state, whether cold or hot, so the oil will always lubricate both the upper and lower gears, greatly extending the life of the machine.

FULL INTERNAL WIRING – BDS magnetic drills have full internal wiring. The motor cable leading from the motor to the housing is installed inside the machine instead of outside. Since no cables are pulled out to the outside, there are no mechanical malfunctions or accidents due to interference from external cables.

The German magnetic drilling machine MAB 855 is a high performance machine for drilling larger holes. The MAB 855 has a drilling capacity of 75 mm in diameter and a 10 mm depth of cut. The MAB 855 magnetic drill machine is his 4 speed geared machine with a grease gear motor. Additionally, this magnetic drill is equipped with an MK3 Morse taper, allowing the machine to use conventional twist drills up to 31.75 mm in diameter. The MAB 855 magnetic drill weighs only 25 kg. He comes in two variants, 230 V and 110 V, with a motor power of 1700 watts.

World’s strongest magnetic drill, made in Germany – MAB 1300. This strongest magnetic drill meets all expectations in heavy industry, shipbuilding, PEB construction, wind turbine construction and more. The all-rounder MAB 1300 magnetic drill can perform core drilling up to Ø 130 mm (Ø 5-1/8 inch) and thread cutting up to Ø M42 (Ø 1-5/8 inch).

MAB 1300 – The World’s Most Powerful Magnetic Core Excavator – Exceptional Performance with Exceptional Power Development. The MAB 1300 is the most powerful magnetic core drill machine available today. Just look at the machine to get an idea. 2300 Watt motor power, 4-speed gearbox, Morse cone 4, single phase, fully equipped for all requirements. The magnetic drilling machine MAB 1300 reaches the limits of magnetic drilling technology.

MAB 1300 – Pure Power

The MAB 1300 Magnetic Drilling Machine comes standard with a direct mandrel with a 32 mm Weldon shank (1 1/4 inch) and an MK 4 Morse taper.

If you remove the bezel in no time, the stroke of the machine can be extended to a whopping 310mm.

The MAB 1300 magnetic drilling machine is fully equipped with all the safety measures of current magnetic core drilling technology.

Machine overheating protection, tool damage protection, worn carbon brush warning, and insufficient magnetic holding power warning. The MAB 1300 Magnetic Drilling Machine comes standard in a rugged carrying case with casters made of impact-resistant plastic. This makes it very portable and easy to handle, despite its weight of 51 kg.

It helps reduce power consumption.

The outstanding features of the MAB 1300 magnetic drill are servo-assisted power feed, permanent internal lubrication, friction clutch, torque control, speed control, full shaft control electronics, magnetic stick indicator, overhead protection, switchable motor, oil bath gearbox, and carbon. such as a brush wear indicator.

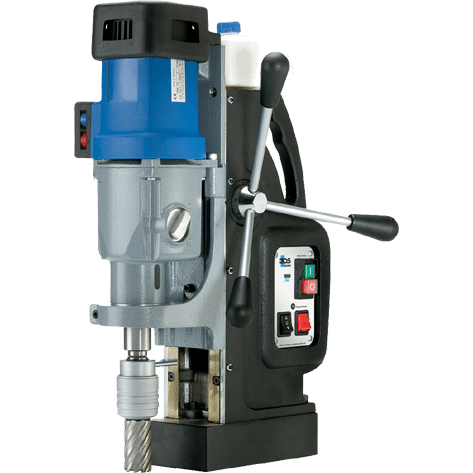

The MABasic 200 Portable Magnetic Drill is our most popular and best-selling drill. The MABasic 200 is the most affordable German made portable magnetic drill available on the market today.

High performance – low price. With this new machine concept, BDS Maschinen bridges the gap for professional users who can achieve comfort and low prices without compromising on quality and performance.

His affordable MABasic 200 portable magnetic drill is equipped with a powerful 900 watt (8.20 amp) German motor. MABasic 200 is available at 230 and 110 Volts, 50-60 Hz. The MABasic 200 Magnetic Drilling Machine has a working stroke of 160 mm (3 1/3 inches).

This lightweight portable magnetic drill weighs only 12 kg (26 lbs) and is equipped with a Weldon direct arbor. The gearbox is greasy and the speed is 450 rpm.

This premium quality portable magnetic drill can perform a 32mm (Ø 1-3/8″) diameter core drill, a 55mm (2 11/64″) depth of cut and a 13mm diameter twist drill. A specially manufactured “BDS generationTwist Drill with Weldon Shank (SPS)” allows the MABasic 200 to be used without a drill chuck holder.

The new portable magnetic drilling machine MABasic 200 is equipped with an “attached” coolant tank.

Made in Germany, the MABasic 400 is a magnetic drill especially suitable for twist drilling. Thanks to its two-speed motor with a high speed of 760 rpm, this machine is extremely fast and robust for drilling with conventional twist-hi drills. We recommend the newly developed “BDS twist drill with Weldon shank (SPS)” for this magnet drill.

The MABasic 400 Magnetic Drill has diameters up to 16 mm (Ø 5/8″) for twist drills, diameters up to 35 mm (Ø 1-5/8″) for core drills, and 55 mm (2 11/64″) can be drilled. cutting depth.

It weighs only 12 kg. (16 lbs.) The MABasic 400 magnetic drill is equipped with a heavy duty 1050 watt (9.5 amp) German brand motor, available in both 230 and 110 volt versions. The MABasic 400 Magnetic Drilling Machine has a stroke of 160 mm (3 1/3 inches), so it is also suitable for twist drills. The MABasic 400 magnetic drill is equipped with a 19 mm (3/4 inch) direct Weldon arbor.

This new generation of his MABasic 400 Magnetic Drilling Machine comes with a coolant tank and a sturdy carrying case.

The German MABasic 450 Magnetic Foot Drill is the most affordable machine with Morse taper from the BDS machine. The MABasic 450 Magnetic Foot Drill is a robust machine with Morse Taper 2 (MK2), so the machine can also be used with conventional drills with tapered shanks.

The MABasic 450 drill with magnetic base has a drilling capacity of 40 mm (Ø 1-3/4 inch) diameter, 55 mm (2 11/64 inch) depth of cut, 16 mm (Ø 3/4 inch) core drill diameter with twist drill. The new product “BDS Weldon Shank Twist Drill (SPS)” is recommended for use with this magnetic base drill.

This magnetic base drill comes with dual speed grease gears of 250rpm and 450rpm, respectively. The German brand motor is 1150 watts (10.5 amps) and is available in 230 and 10 volts depending on your needs.

It weighs only 13 kg (29 lbs). The MABasic 450 Magnetic Foot Drill comes with a coolant tank installed. The MABasic 450 Magnetic Foot Drill comes in a sturdy carrying case.

The MABasic 850 is a heavy-duty magnetic drill made in Germany with a very powerful 1700 watt (16 amp) motor. The MABasic 850 Magnetic Drilling Machine has 4 speeds of lubricated gears at 110, 175, 245, or 385 rpm.

This heavy-duty magnetic drill is a Morse Taper 3 (MK3) machine, so you can use a conventional twist drill with a tapered shank up to 31.75 mm (Ø 3-1/16 inch) in diameter. The MABasic 850 magnetic drill can drill ring drills up to 75 mm (Ø 3-1/16″) diameter and cutting depths of 75 mm (3-1/16″).

This is the highest capacity magnetic drill in the ProfiBASIC category of machines, a powerful and affordable magnetic drill.

The MABasic 850 magnetic drill is available at 230 and 110 volts at 50-60 Hz. The magnetic drill weighs 25 kg. (55 lbs) and has a powerful electromagnet. Additionally, the MABasic 850 Magnetic Drilling Machine comes with a coolant tank installed and comes in a rugged shipping case with accessories such as ejector pins, industrial mandrels, offset screwdrivers, and safety lashing straps.

The Premium AutoMAB 350 Automatic Feed Magnetic Drilling Machine is a fully automatic magnetic drilling machine made in Germany with automatic feeding and reversing functions. Machines are the future of magnetic drill technology because of their many advantages. Some of the advantages of automated machines are: 1. One operator can operate multiple machines; 2. Machines are self-contained, eliminating operator error and avoiding tool breakage. 3. It can be operated by inexperienced operators.

A great feature of the AutoMAB 350 automatic feed magnetic drill is a load gauge that indicates the load on the machine. If the load is too high, the machine’s engine will automatically stop to prevent tool damage. A magnetic gauge that tells the operator whether the thickness of the material being drilled or the surface of the material is sufficient for proper magnet attachment. If the material is not suitable for magnet adhesion, the LED magnet indicator will turn red and the machine’s motor will not start. An automatic stop that can stop the engine of the machine when full reverse feed is achieved after drilling is achieved.

One very interesting feature of his auto-feed AutoMAB 350 magnetic drilling machine is that the machine also has the option of manual drilling. This is very useful for manually locating hole centers and drilling very hard materials.

His AutoMAB 350 automatic magnetic excavator with a 1050 watt (10.5 amp) German brand motor is available at 230 and 110 volts at 50-60 Hz. The AutoMAB 350 is a single speed machine with a 19mm (3/4 inch) direct Weldon arbor. The AutoMAB 350 magnetic drilling machine with automatic feed has a working stroke of 160 mm (3 1/3 inches). This lightweight auto-feed magnetic drill weighs just 15 kg. (33 lbs). It is very portable and convenient. The AutoMAB 350 automatic magnetic drilling machine is equipped with state-of-the-art LED switches for power and magnets. The AutoMAB 350 Magnetic Drilling Machine comes in a sturdy carrying case.

The self-feeding AutoMAB 350 magnetic drill has a drilling capacity of 35 mm (Ø 1-1/2 inch) diameter and a 55 mm (2 -11/64 inch) cutting depth.

Manufactured in Germany, the AutoMAB 450 automatic magnetic excavator is the more powerful model in the AutoMABs series of fully automatic excavators. The AutoMAB 450 is a powerful Morse Taper 2 (MT2) machine, supplied with an industrial mandrel with a 19 mm (3/4 inch) Weldon shank for use with ring cutters.

The AutoMAB 450 automatic magnetic excavator has a load indicator that reliably monitors the excavation process, and the power consumption is displayed via LEDs. An automatic switch-off protects the drill motor from overload. Safety Controlled Shutdown Drill and feed motors automatically shut down when the magnet loses grip. A magnetic gauge that tells the operator whether the thickness of the material being drilled or the surface of the material is sufficient for proper magnet attachment. If the material is not suitable for magnet adhesion, the LED magnet indicator will turn red and the machine’s motor will not start.

The advantage of the magnetic drilling machine is the high drilling uniformity. This protects the tool and machine and greatly reduces the risk of core drill breakage.

The AutoMAB 450 automatic magnetic drill with a 1150 watt (10.5 amp) motor is available at 230 and 110 volts at 50-60 Hz. The grease motor has two speeds, the output is 250 and 450 rpm respectively, and the working stroke of the machine is 150 mm (5 29/32 inches).

The automatic magnetic drilling machine AutoMAB 450 weighs only 16 kg. (35 lbs) and has a very strong magnet. The AutoMAB 450 automatic magnetic drilling machine has a drilling capacity of 45 mm (1 49/64″) diameter with a ring cutter and a depth of cut of 55 mm (2 -11/64″).

The AutoMAB 450 can be used as an automatic feed or as a manual feed by pushing the handle towards the machine to activate the automatic drill feed. The AutoMAB 450 automatic magnetic drilling machine comes in a sturdy carrying case.

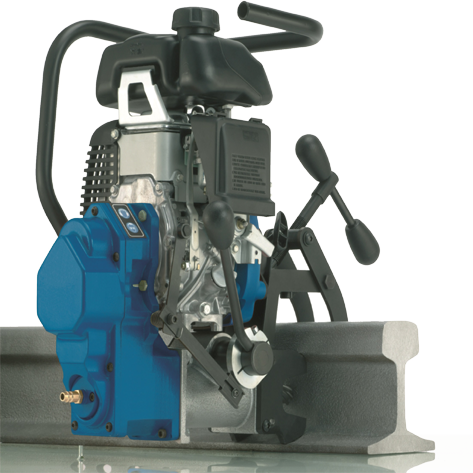

In the area of rail machining, BDS offers two completely new rail boring machines that have been completely redeveloped.

German RailMAB 915 rail boring machine with 1600 watt motor and two-stage oil bath gearbox and RailMAB 965 rail core boring machine with petrol engine.

The electric rail excavator RailMAB 915 and the petrol rail excavator RailMAB 965 are special rail excavators used in the construction of tracks and signals, for example for excavating grounding screws, contact systems and insulating joints. The RAilMAB 915 is a Morse Taper 3 (MT 3) machine.

Both rail drill machines are easily attached to the rail with a quick release system. This puts 1.2 tons of pressure on the rail foot to ensure the required digging stability. A large number of optionally available rail adapters greatly increase the flexibility and ease of use of the 2-rail core drill machine. These adapters automatically determine the height and distance of holes to be made in core drills or rails.

The range of rail drill machines is rounded out by the BDS special rail core cutters of the CarbideRAIL core drill series, with a cutting depth of 30 mm and diameters from 16 mm to 36 mm.

Full Wave Control Electronics – Full wave control electronics allows the motor to provide the same power while drilling as it does at idle.

OVERHEATING PROTECTION – Overloading or improper handling of the machine while drilling can cause the machine to heat up, and the heat can damage the motor. The BDS drill protects the machine from overheating by shutting down the motor when a sensor detects overheating, preventing damage to the motor.

Oil bath gear – The motor gear of the BDS drill is made in an oil bath. The advantage of BDS oil bath gearboxes is that the oil is always in a liquid state, whether cold or hot, so the oil will always lubricate both the upper and lower gears, greatly extending the life of the machine. is.

In the area of rail machining, BDS offers two completely new rail boring machines that have been completely redeveloped.

German RailMAB 915 rail boring machine with 1600 watt motor and two-stage oil bath gearbox and RailMAB 965 rail core boring machine with petrol engine.

The rail boring machine RailMAB 965 is a mains independent rail boring machine with a robust petrol engine. Its power output reaches 1.5 kW with a torque of 3.04 Nm.

Both rail drill machines are easily attached to the rail with a quick release system. This puts 1.2 tons of pressure on the rail foot to ensure the required digging stability.

A large number of optionally available rail adapters greatly increase the flexibility and ease of use of the 2-rail core drill machine. These adapters automatically determine the height and distance of holes to be made in core drills or rails.

The range of rail drill machines is rounded out by the BDS special rail core cutters of the CarbideRAIL core drill series, with a cutting depth of 30 mm and diameters from 16 mm to 36 mm.

The RailMAB 965 is an RDSO certified machine.

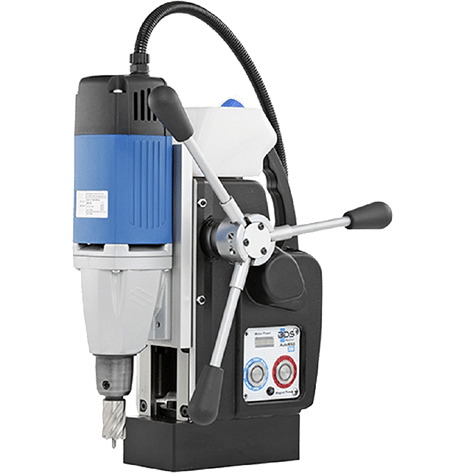

MAB 825 V – automatic core drilling machine. Full power and flexibility for steel, plant and mechanical engineering with adjustable automatic feedrate.

►The automatic feed is activated and deactivated at the turnstile and can be switched on in any position.

►Infinitely variable feed for optimal use of each tool.

►Feeding stops automatically when the top or bottom position is reached.

►By switching manually, the next process is possible at any time.

►Safety Controller Shutdown:

When the magnet no longer holds, the drilling and feeding motors are automatically turned off.

►Same performance data, can also be used with manual loading.

The MAB 825 V magnetic drilling machine can perform core drills up to Ø 100 mm (Ø 4-1/16 inch) in manual mode and Ø 60 mm (Ø 2-23/64 inch) in automatic mode. Thread cutting up to Ø M30 (Ø 1-1/4″) in automatic or manual mode. MAB 825 V – The World’s Most Powerful Magnetic Core Excavator – Exceptional Performance with Exceptional Power Development. The MAB 825 V is the most powerful magnetic core drill machine available today.

Just look at the machine to get an idea. 1800 watts (16 amps) motor power, 4 speed gearbox, Morse taper 3, single phase, fully equipped for all requirements. The MAB 825 V Magnetic Drilling Machine reaches the performance limits of magnetic drilling technology.

MAB 825 V – automatic and manual. The MAB 825 V Magnetic Drilling Machine comes standard with a direct mandrel with a 32 mm Weldon shank (1-1/4 inch) and an MK 3 Morse taper.

The MAB 825 V magnetic drilling machine is fully equipped with all the safety measures of current magnetic core drilling technology.

Machine overheating protection, tool damage protection, worn carbon brush warning, and insufficient magnetic holding power warning.

The MAB 825 V Magnetic Drilling Machine is supplied as standard in a rugged transport case with wheels made of impact-resistant plastic. This makes it very portable and easy to handle, despite its weight of 25 kg. (68 lbs)

The MAB 825 V can also be ordered as the MAB 825 in the manual version only.

Brand new German MAB 825 KTS portable drilling and milling machine from BDS Maschinen GmbH. The MAB 825 KTS is equipped with a magnetic cross table base. The cross table can move 110 mm on the X-axis and 120 mm on the Y-axis. A cross table allows the machine to easily mill keyways, oval holes, offset holes, and hole patterns. The MAB 825 KTS portable milling machine can drill, tap, ream, countersink, and mill thanks to its high performance reversible motor. This portable keyway milling machine is equipped with Morse taper 3, magnetic display, oil bath gear, overheat protection, safety clutch, carbon brush wear indicator, solid shaft control electronics, and more.

The world’s most powerful automatic magnetic drilling machine, MAB 1300 V, has variable automatic feed and variable automatic return.

The advantages of the strongest magnetic drilling machine, MAB 1300 V, are:

► Automatic feeding can be switched on and off with the star handle and can be switched on at any position.

► Infinitely adjustable feedrate for optimum utilization of the individual tools used.

► The feed stops automatically when the top or bottom position is reached.

► Additional work can be done at any time by switching to manual mode.

► Switching off the safety control:

The drill and feed motor will automatically stop when the magnet is removed.

► The machine can also be used with manual loading with the same performance.

The all-rounder MAB 1300 V magnetic drilling machine can perform core drills up to Ø 130 mm (Ø 5-1/8 inch) in manual mode and Ø 60 mm (Ø 2-23/64 inch) in automatic mode. Thread cutting up to Ø M42 (Ø 1-5/8″) in automatic or manual mode.

MAB 1300 V – The World’s Most Powerful Magnetic Core Excavator – Exceptional Performance with Exceptional Power Development. The MAB 1300 V is the most powerful magnetic core drill machine available today.

Just look at the machine to get an idea. 2300 Watt motor power, 4-speed gearbox, Morse cone 4, single phase, fully equipped for all requirements. The MAB 1300 V magnetic drilling machine reaches the limits of automatic magnetic drilling technology.

MAB 1300 V – automatic and manual.

The MAB 1300 V Magnetic Drilling Machine comes standard with a direct mandrel with a 32 mm Weldon shank (1 1/4 inch) and an MK 4 Morse taper. If you remove the bezel in no time, the stroke of the machine can be extended to a whopping 310mm.

The magnetic drilling machine MAB 1300 V is fully equipped with all safety measures of current magnetic core drilling technology.

Machine overheating protection, tool damage protection, worn carbon brush warning, and insufficient magnetic holding power warning.

The MAB 1300 V Magnetic Drilling Machine comes standard in a rugged transport case with impact-resistant plastic casters. This makes it very portable and easy to handle, despite its weight of 51kg. (112 lbs)

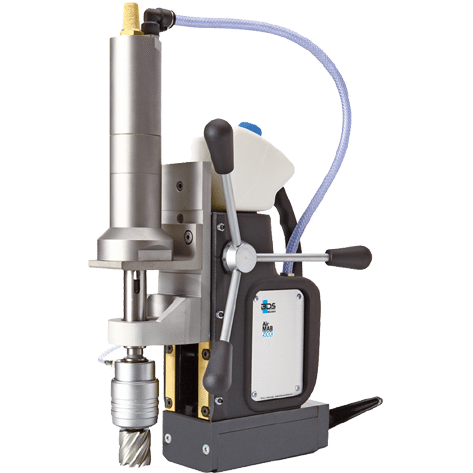

German Pneumatic Magnetic Drilling Machine AirMAB 5000 – Drilling with pneumatic drive and permanent magnets.

High performance vane motor. Motor approved according to EX class Ex II 2G T4 IIC D110°C

The AirMAB 500 pneumatic magnetic excavator is equipped with a powerful and robust 830 watt motor. This motor was specially manufactured by Atlas Copco for his BDS Maschinen GmbH. The motor offers a nominal torque of 27 Nm and an average air consumption of 1000 l/min.

The air intake can be controlled with a button on the side of the machine. The AirMAB 5000 pneumatic magnetic drilling machine has a stroke of 160 mm and weighs only 17.5 kg. (38 lbs)

A great feature of the AirMAB 5000 is that it is equipped with a keyless drill chuck system. The AirMAB 5000 is a Morse Taper 2 (MT2) machine and can also use tapered shank twist drills up to 23mm in diameter.

This pneumatic magnetic drill is completely independent of electricity, and the magnet of the machine is a strong permanent magnet, which can be magnetized and demagnetized with a switching lever.

The BDS MABasic 35 is the new benchmark for delivering German quality at a reasonable price. It comes with a powerful 1050 Watt motor that can drill precise holes in varying types of metals.

The BDS MABasic employs an advanced magnetic technology that allows it to be used in multiple industrial scenarios, such as building, fabrication, and engineering. It has a maximum core drilling diameter of 35 mm and a cutting length of 55 mm. The switches are arranged on the top, making it easy to operate.

The machine is relatively lightweight and can be operated both horizontally and vertically. To prevent overheating, the machine is equipped with a cooling tank on the side. It comes with a rust-free design, ensuring longevity and durability under harsh industrial conditions.

The BDS MABasic 50 is a new magnetic machine from the brand BDS that has superior prior for drilling and is also easy to use. The machine does not weigh much—only 13 kg—and can be easily carried around, making it ideal for most industrial work scenarios.

The drill has been designed in Germany and consists of two varied speed modes, catering to a wide range of industrial requirements. There are multiple types of drills available. The short ones can dig up to 30mm deep, and the longer ones can dig up to 55 mm in depth. The machine comes with twist drilling that can execute drilling operations up to 18 mm in depth with the right adapter.

The BDS MABasic 50 also comes with an additional carrying case, which will keep the machine safe. It is easy to carry and portable, and it comes with a directly mounted coolant tank.

BDS Maschinen presents the next generation of beveling machines. They provide four types of beveling machines, which are:

- Automatic Feed Plate Beveling Machine

- Portable Plate Beveling Machine

- Chamfering Machines

- Heavy Duty Chamfering Machines

BDS beveling machines are designed to operate at various angles and depths. This ensures flexibility with various industrial requirements. Built to thrive in the toughest of industrial scenarios, the machines are reliable for years to come. With precise engineering, the machines ensure that every cut is perfectly aligned to meet the most stringest quality standards.

All the beveling machines are easy to operate due to intuitive controls and ergonomic features. This increases productivity and reduces operator fatigue. All machines come equipped with protective guards, emergency stop buttons, and safety interlocks to keep the operators safe during work.

With BDS Maschinen, you can trust that every beveled edge will meet your exacting standards.

BDS Maschinen GmbH is one of the few manufacturers in Europe that 100% manufactures annular cutters in its own factory in Germany. These cutters are built using the best raw materials from Böhler Steel and on high tech modern grinding centers. BDS has two primary types of annular cutters.

- High-Speed Steel (HSS) Annular Cutters

- Tungsten Carbide Tip (TCT) Annular Cutters

The BDS annular cutters are available in varying sizes, from millimeters to inches. There are three types of HSS available, depending on the material used to manufacture them.

- HSS-Cobalt 8% HSS Annular Cutters are made from M42 HSS. They are used to drill through harder materials.

- HSS-VarioPLUS Annular Cutters are made from M2 HSS and come with an extra hard coating for a smooth finish.

- HSS-Standard Annular Cutters are made from M2 HSS and are suited for normal drilling applications.

The TCT annular cutters are also available in three types.

- Carbide Standard TCT Annular Cutters are used for drilling hard materials and have a large diameter size.

- Carbide-PLUS TCT Annular Cutters have the best resistance and are well suited for materials like stainless steel, HARDOX, INOX, etc.

- Carbide-RAIL TCT Annular Cutters are used in railway applications and are capable of drilling through corroded materials.

All of the annular cutters are available in the standard sizes of 30, 55, 75 and 110 mm cutting length. Also, the diameter has a wide range from 12 mm to 130 mm as standard.

For Product base solutions, to know & try the products in our offerings, to call for Technical discussions with our Sales & Product Engineers.