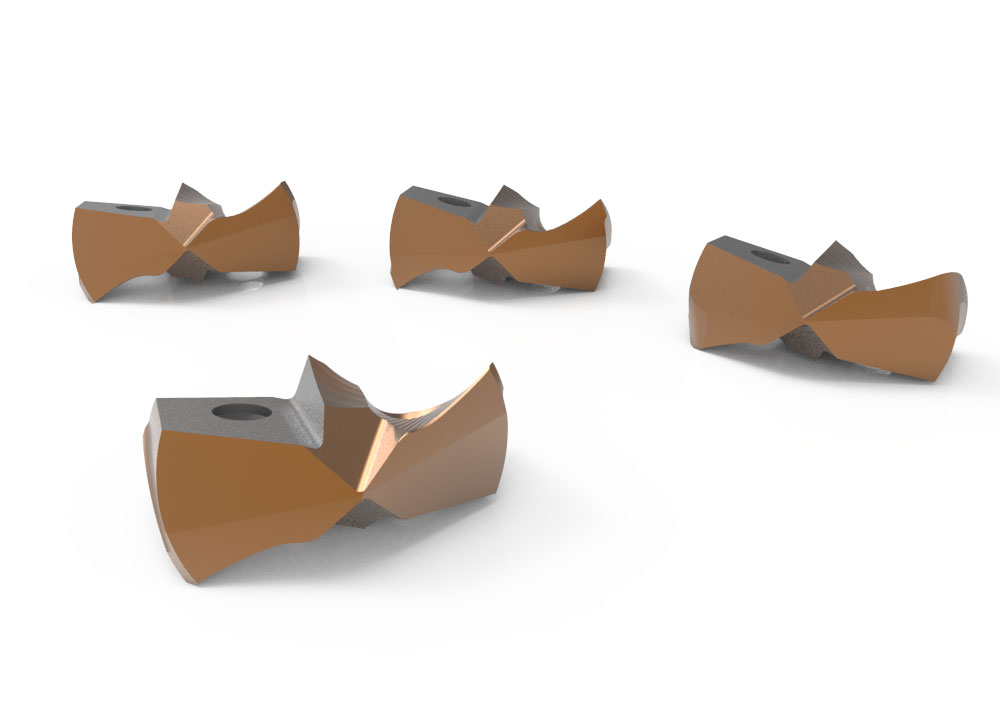

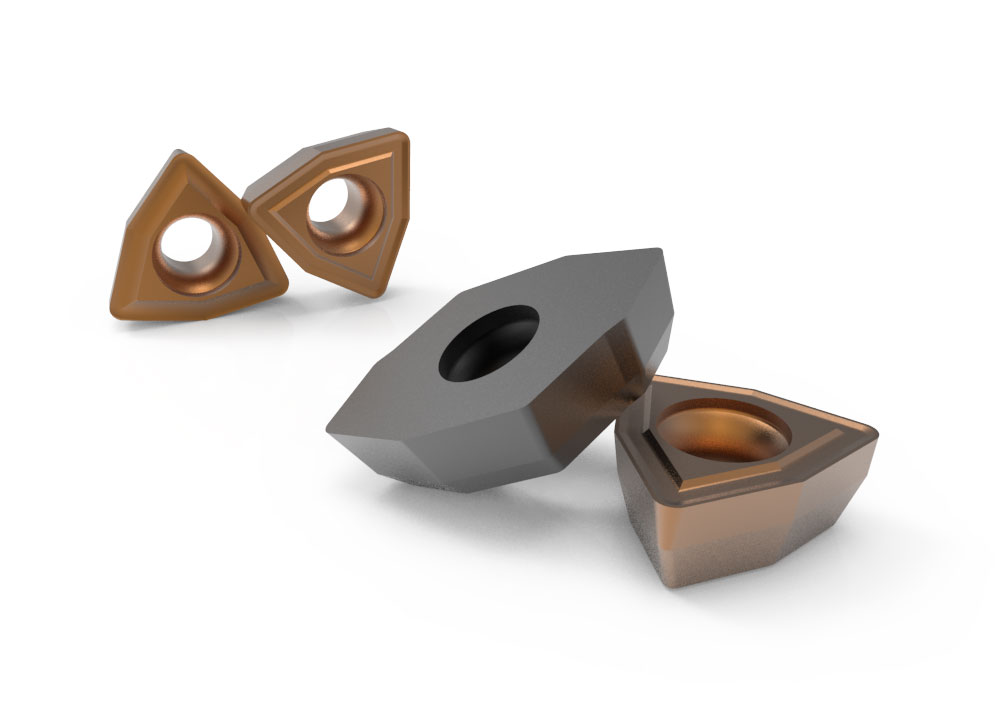

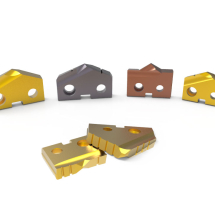

Allied Machine and Engineering is a renowned global manufacturer of precision cutting tools, serving industries such as aerospace, automotive, and energy. With a commitment to innovation and quality, they have earned a reputation for providing cutting-edge solutions for machining applications worldwide.

Allied Machine and Engineering recognizes that every requirement is different and they put an emphasis on providing custom solutions. Quality is at the heart of industrial cutting tools that bear the Allied Machine and Engineering name. They have rigorous quality assurance processes that include precision testing and inspection. All of this is what goes behind the quality output.

In line with the growing emphasis on sustainability in manufacturing, Allied Machine and Engineering also focuses on eco-friendly practices. They work towards reducing environmental impact through responsible manufacturing processes and materials sourcing, reflecting their commitment to a greener future.

For Product base solutions, to know & try the products in our offerings, to call for Technical discussions with our Sales & Product Engineers.